Our Process

Fabric Dyeing Process

To dye fabric, the process demands a full day's commitment and begins with the preparation of bark or other natural items to extract the desired dye.

After boiling these materials for an hour, the yarn is introduced into the mixture and allowed to simmer for another hour, absorbing the rich hues.

The yarn then undergoes a thorough washing to ensure the dye sets properly, before being left to air dry for a day to a day and a half.

Yarn Preparation

Before weaving begins, we prepare our yarn to ensure the highest quality and smoothest weaving experience.

We carefully unwind the yarn from its skein or hank, we avoid any potential tangles.

Then, we wind the yarn into compact balls using a yarn winder or our hands, adjusting the size to fit the width of our backstrap loom and desired weaving density.

Throughout this process, we maintain consistent tension to facilitate flawless weaving. Once prepared, the yarn is attached to the backstrap and heddles of the loom, ready to be transformed into intricate patterns and designs.

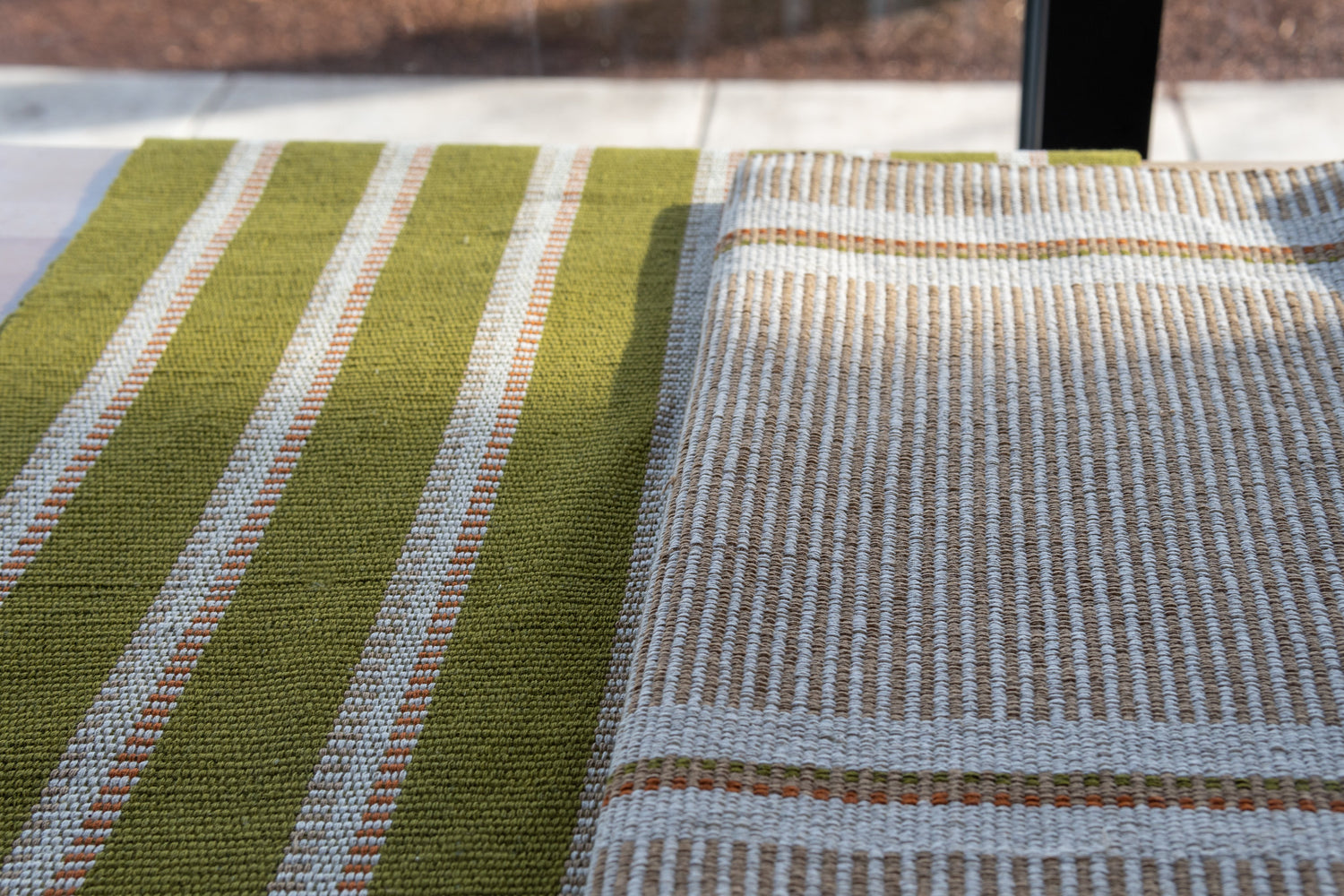

Weaving

The final step in our backstrap loom weaving process is the weaving itself, a labor of love that can span anywhere from one to three days for each individual item.

This stage is where creativity meets craftsmanship as we carefully manipulate the tension, sheds, and pattern sequences to achieve the desired texture, color, and design intricacies.

Each pass of the weft thread contributes to the unfolding story of the piece, showcasing the unique blend of tradition and innovation that defines our work.